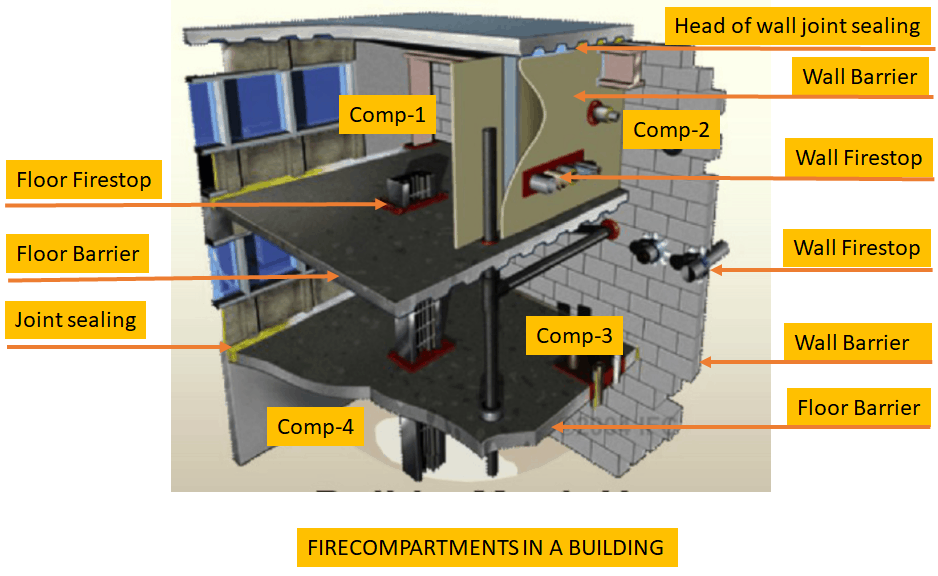

Propagation of fire causes multiple death and immense damage. Containment of fire, near to source is the best way of protection, thereby allowing time for evacuation and fire suppression activity. Hence Compartmentation is carried by dividing a large premises in to number of smaller rooms. The wall and slab of fire compartment are named as fire barriers that can resist fire for a period like 60 or 120 or 240 min etc. These barriers (walls & slabs) have opening for passing various MEP services like electrical (Cable, Trays , Busbars), Mechanical ( Airducts, Ac ducts, Steam pipes) and Plumbing (Plastic, steel , CI pipes) . There may be gaps at joints of barriers for expansion purpose. These openings and gaps are path for fire spread and the wall or floor looses its fire rating. Hence these opening are to be sealed properly for retaining the fire rating of walls and floor.

What is a Firestop

The process of sealing of the opening in fire rated barriers (Walls and floors) for regaining of fire resistance is called firestopping. In simplifying, Firestop prevents propagation of fire from source side to un- exposed side. The fire resistance of these sealing (Firestop) is same as the barrier rating.

What Code says

International Building code ( IBC 2015) makes it mandatory to seal the opening directly with a tested design that gives evidence of same fire resistance. National Building code (NBC 2016) of India mandates for sealing these opening with appropriate firestopping to re-establish the fire resistance of the barriers. Indian standard 12458 – 2019 specify the fire stop tests but is not so comprehensive on appropriateness of system to be installed with direct evidence. Hence fire stops designs are always pretested with similar penetrations.

What is an appropriate Firestop

Flame resistance of firestop: A firestop design should be such that its size should match the size of opening and it should resist propagation of flame of that size. Further the design should have same kind of combustible penetrations as in the opening with same or more fuel load. These two factors combinedly provides Flame resistance character. It is known as F rating (Flame resistance) in UL 1479.

Temperature Resistance of firestop: The temperature from exposed side of barrier passes to unexposed side due to conductions and radiations through metallic penetration and firestop. The temperature passed to unexposed side can ignite combustible material. Hence a suitable design shall give evidence of being tested with similar no of metallic mass and not causing fire other side. In UL 1479, it is known as T rating or insulation resistance.

Integrity and pressure resistance: In presence of fire, metallic penetration like duct, pipes may expand and sag at firestop opening to bring damage during fire. Subsequent to fire test, water pressure is applied by a hose known as hose stream test . The objective of test is observe if the integrity of firestop is intact during fire suppression activity. A large sealing construction to sustain hose stream require to be tested in original size.

An appropriate design of firestop for an opening should have

- Been tested for wall or floor as required to be sealed.

- Been tested for same or more fire resistance.

- Size same or bigger than the opening,

- Same type, same size or bigger penetration.

- Same or more number of penetration.

- similar annular space or position of penetration with respect to barrier edge.

These limiting parameter or conditions are well explained in listed designs.

Interpretation of Certified product or Design

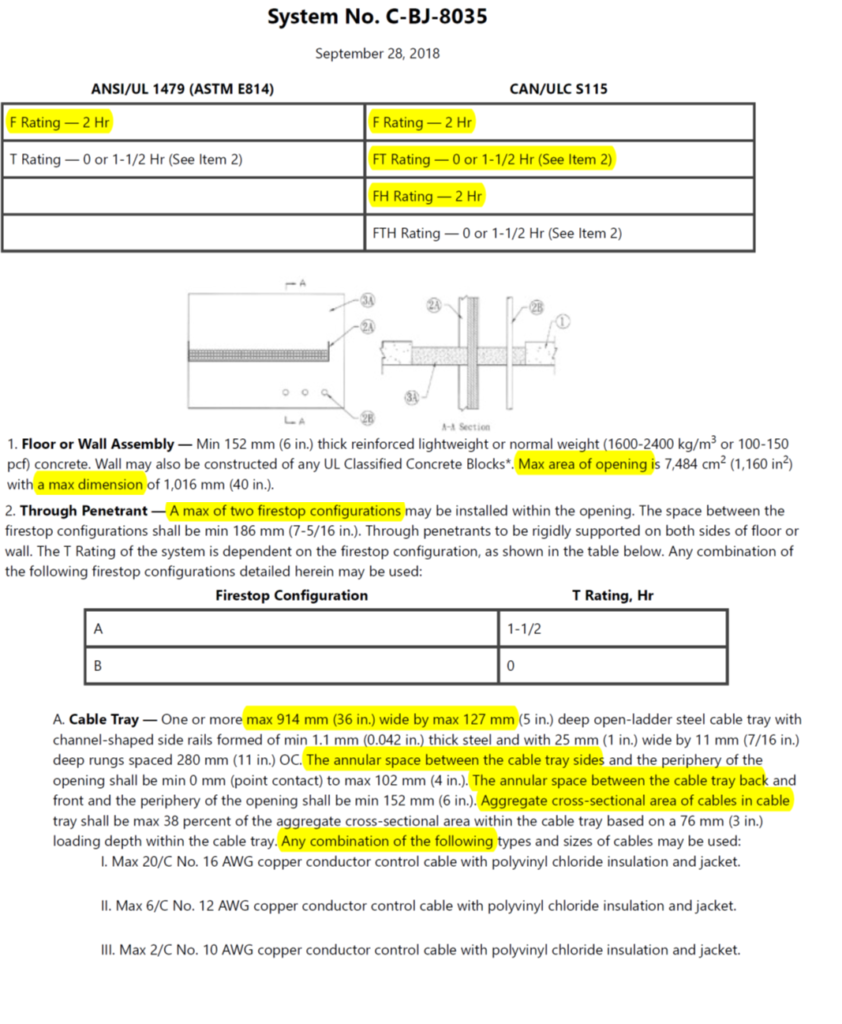

UL 1479 OR FM 4990 Designs : UL1479 or FM 4990 are equivalent test standard of firestop equivalent to ASTM E 814, which is accepted all over the world. A firestop design tested by these are also documented in their on line web directory for public reference as Certified firestop design. The certified designs are followed on a planned basis for their renewal from time to time. The certification is considered to be obsolete or invalid, once the design is dropped from on line directory.

Listed Design compliance : A firestop design listed under UL 1479 / FM 4990 guarantees that on installation of it in prescribed manner in an opening having defined size, dimension, penetration type , penetration quantity and locations etc, shall fully comply the fire resistance and such firestop can then bear the UL or FM Mark.

Firestop Material compliance to UL/FM : A firestop material is labelled with UL / FM marks, when the material is part of one or more listed firestop design of UL or FM for meeting sealing requirement.

Some clarification:

- If a design and its installation complies fully to the situation, it is considered as an appropriate firestop and shall provide the desired fire resistance and When a listed design selected is not fully compliant to a situation, the design is considered as in- adequate or in-appropriate. For application of non compliant design, an engineering judgement with proper explanation shall be warranted. It should be noted that engineering Judgements are issued only in special cases but can not be used for multiple deviations.

- Many companies having one or two designs listed under FM 4990 or UL 1479 misleads, the suitability of these designs for all types of situation. There is no universal fire stop design suitable for every opening. Every opening and penetrations are unique may require separate design.

- By thumb rule, if there is no certified design available for a situation, nearest design shall be used with Engineering Judgement. Hence companies having more number of listed designs shall be suitable for handling multiple variety of opening. Reputed firestop companies have UL designs exceeding hundred number to few thousands.

Other Considerations for selection of firestop design.

- Different firestop material are used for different size of barrier.

- Some material are suitable for outdoor firestopping.

- Some specification may require smoke resistance and water resistance. A fires top is not smoke resistant or water resistant if it is not reflected in the design document.

- Joint sealing are not governed by same standard as through penetrations. The joint sealing specification require a percentage of shrinkage and expansion.

- Perimeter or curtain wall barrier are tested in special standards.

Summery

Proper selection of design for each situation , require detail survey of openings and selection of a suitable designs. Further some opening may be altered to meet the firestop design selected. In cases where, no design meets a special requirement, Engineering Judgements are released from OEM to meet the situation. Effectiveness of a firestop is based on suitable design selection. There is no universal tested design which suits for all situations.