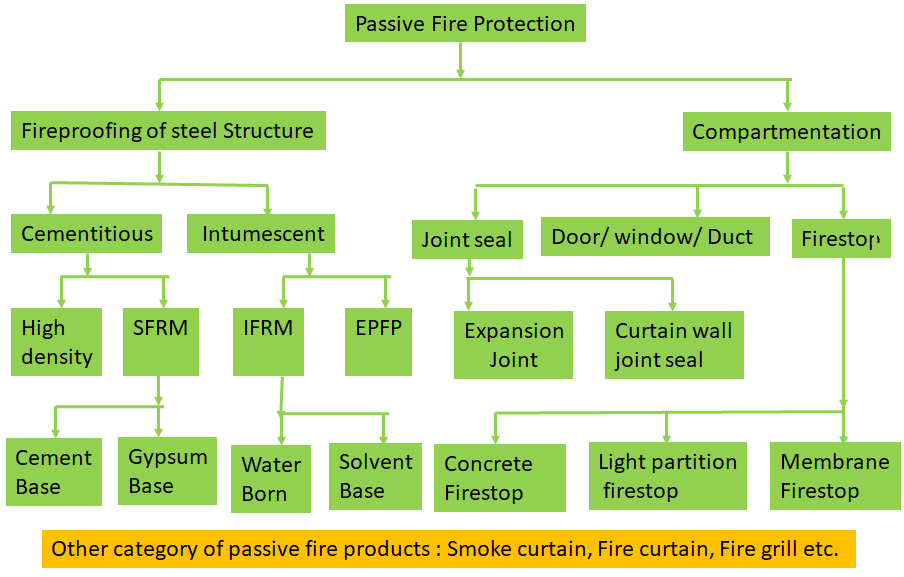

Passive fire protection (PFP), broadly consists of two major areas and many more subareas. Fireproofing of supporting structures (Beams, Columns, Floor, roof, wall assembly) are to be protected for integrity of building incase of fire . Second area of PFP is Compartmentation, aimed to create safe egress through localising the fire near to its source. The picture below gives a general detailed view of PFP . International building code 2015 gives guidelines for items showen up to 4rth level in the below picture. Fifth level defines suitability of material and types of firestop. To meet varied situations, there are various test standards, materials and standard procedures.

Who are concerned on such diverse aspects of fire protections?

International Building code in chapter 17.5 makes it manditory for special inspection in most of the PFP areas . Various parties concerned for PFP are : local authority for risk assessment, the owner of property for protection of occupancies, the fire protection designer for effectiveness, the execution contractor for value of money, the fire protection material supplier for warranty and reputation and the installer for the liability. Role of inspector is defined in International building code with inspection parameters, standards for inspections, sampling standards etc for fire proofing, for fire stopping, for joint sealing and for curtain wall joint sealing . However, NBC 2016 while code require compliance for all the fire protections elements mentioned above but NBC has not covered special inspection criteria. But the moot point is whether a special inspector or third party inspection is just another technical obligation or a need that provides value for the protection areas.

Difference between PFP inspector and normal Inspector.

PFP is new area of study by it self and is continuously evolving as construction sector is undergoing technological and architectural change. Construction professionals, being engineer from electrical, mechanical or civil stream shall find the subject different than their stream. The diffrence is not limited to engineering but the detail understanding of fire test, judgement, codes, standards, certifications, situation, complying norms and so on. Hence a normal inspector require understanding and experience of PFP as a PFP inspector. IBC 2015, AWCI Technical manual 12 A, International Firestop council(IFC) , International code council (ICC), ASTM E etc prescribe qualification and experience for the PFP inspection, while most of these recognise certified inspector through test or examination.

Role of PFP Inspector

A PFP inspector is responsible to

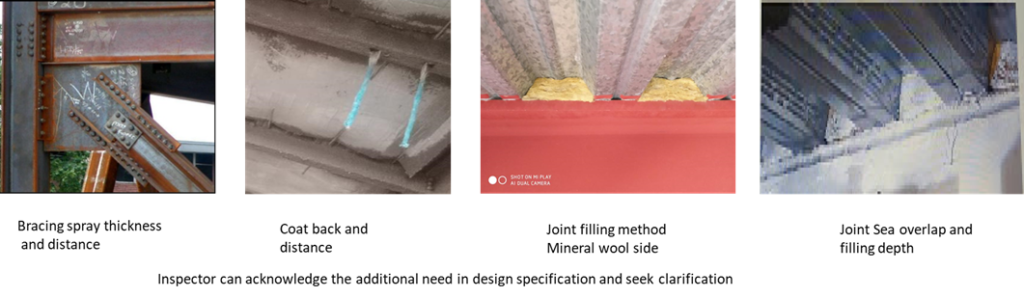

- Record the PFP designs to be installed , quality control parameters advised by consultant. In case of gaps, or no clear specification, he shall request for details. He shall work for technical liaison between local authority, Designer, OEM, Contractor, Owner and Installer.

- Participate in all site meeting to understand plan, target and communicate observations. In case, the installation process does not comply the design specification, the inspector shall be in option to modify the plan. Example an inspector may defer the work if the application process require previous applied material to be dry before work.

- Inspect material for certification mark and for general quality. Inspector shall ensure documental evidence for quality of batch parameters. Shall record if all materials are as per drawing and and also record storing condition.

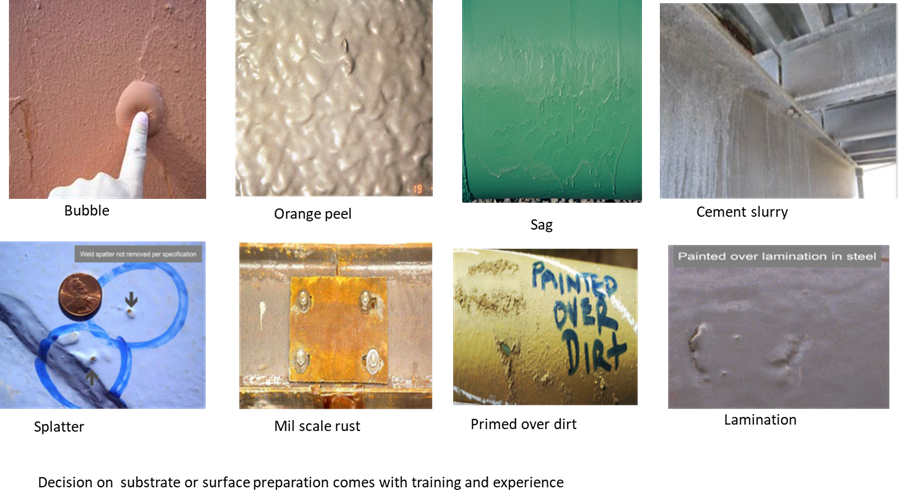

- Initate for making of mock up, for defining the apperance quality and checking if surface is adequete to meet the requirement of the design or the standard.

- The inspector shall also record the machines and tools used are comlying to method statement. Inspector shall also check ambient condition of site on rutine basis before start of work at site.

- Guide or answer technical requirement to installer. Keep all approval certificates and technical documents, all measurement doccuments.

- Inspector being technically responsible, shall give his observation if application process is inadequate to the design followed, or the method statement or OEM advice or product data sheet.

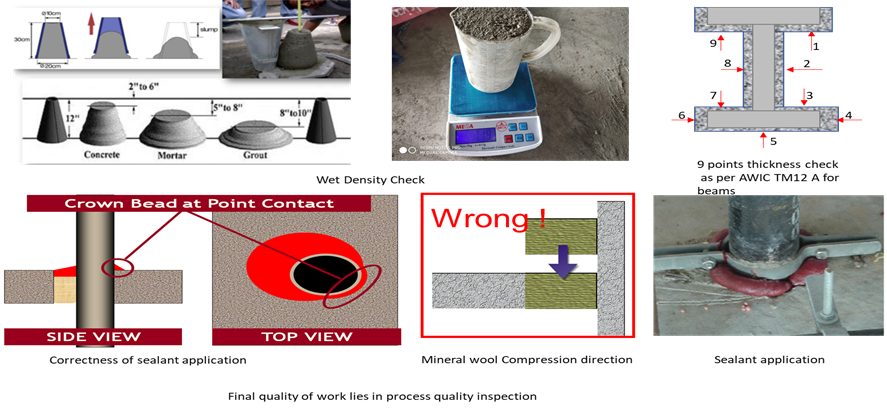

Final Inspection

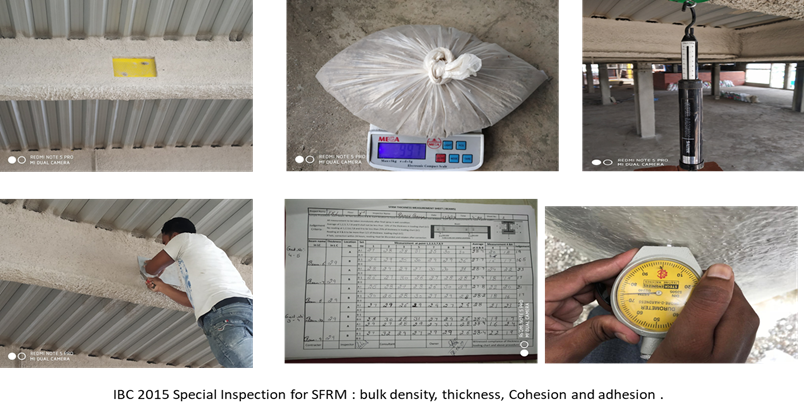

Building code advises for special inspection of some fireprotection control parameters for compliance to code. Inspector shall test such parameters directly or through third party laboratory. Testing of these parameters are carried as per prescribed standards and sampling norms. These tests are applicable for Fireproofing (SFRM and IFRM), Firestop, Perimeter barrier and so on. Some of these tests are destructive. Inspector being experienced 3rd party technical person, carryout such activities. Inspector is also part of final certification and warranty process. Hence, the inspector also compile all documents (inspection data, certificates and evidence) as fire protection record and for future maintenance.

Summery

Passive Fire protect being a special field, third party inspector of PFP works as a passive fire protection engineer on behalf of Fire authority & Owner. The design shall only perform for fire protection, if it is assured to be installed properly . Hence the inspector become quality manager for the designer, OEM , contractor and installer. Objective of Passive fire protection is much more significant than only to inspect a civil or electrical work. Fire can affect not only the occupancies but lives in the vicinity, if intallation of fullproof design has many shortcomings. Hence the role of inspector is to ensure the protection of life, compliance to the design, fire protection norms, standard and Code.