Curtain Wall Joint Sealing

The curtain wall joint sealant acts as a fire barrier that slows the progression of fire, heat and smoke between floors of multi-storey buildings.

- With the increase in construction of high rise buildings, International building code (IBC) and National building code (NBC) added new fire protection areas.

- Perimeter seal or Curtain wall joint seal.

- Firestop Joint seal

Perimeter seal or Curtain wall joint seal.

Curtain wall joint seal :

- Building codes requires fire resistance of floor to be extended to outer wall.

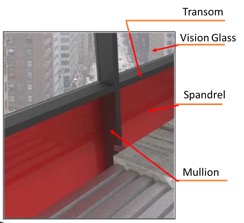

- Glazed outer wall or curtain wall are installed leaving a gap of 100 to 300 mm.

- In case of fire in lower floor, the gap become path like chimney for spreading smoke , Heat and Fire

Path of fire propagation could be through gap, through outside and also through mullion.

Curtain wall joint seal works as

- Fire barrier

- Smoke barrier

- Acoustics

- Preventing loss of air-condition energy

- A physical barrier for dust etc.

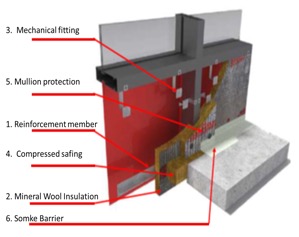

Six stages of Curtain wall sealing

Standard : ASTM E 2307

Important

Considerations :

- Floor construction type

- Curtain wall construction type

- Joint width

- Movement requirement

- Fire rating

- Smoke rating

- Firestop material

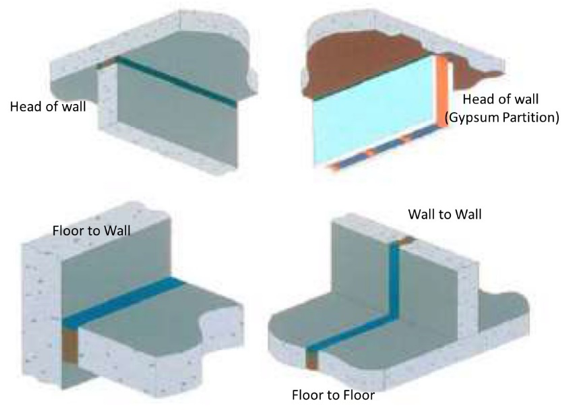

Firestop joint seal

Joint between fire resistance rated assemblies shall be protected by an approved fire resistance joint system designated to resist the passage of fire for a time period not less than the required fire resistance rating of the assemblies in which it is installed.

- Such barriers have L rating for smoke prevention, not in excess of 5 CFM.

- These may have various expansion/ compression %

- Joints are tested against UL2079 standard.

- A joint may be floor- floor, floor – wall , head of wall , wall to wall.

Standard : ASTM E 1966

Important

Considerations :

- Type of joint

- Nominal width

- Movement requirement

- Fire rating

- Smoke rating

- Firestop material depth

- Backer plate

Still have questions?

Phone: